Tackling Food Waste with Smart Automation

Food waste is a global challenge, and processors are at the forefront of reducing avoidable losses right at the source. By transforming inefficient factory methods, we can dramatically cut the food lost or wasted during production.

The key? Equipping processing lines with advanced automation technologies. Solutions that deliver a powerful impact, minimizing waste while boosting efficiency. It starts with understanding where and why food loss happens in your production process.

That’s step one. Step two is deploying the right technology - a game-changing tool for resource optimization.

Our high-speed, precision de-coring systems for lettuce, cabbage, cauliflower, and broccoli are designed to do just that. Built on years of family-driven expertise, our machines maximize yield, reduce waste, and streamline operations with seamless, crop-specific automation. Available in single or twin-lane setups, they integrate effortlessly to elevate your process.

Automation isn’t just about productivity - it’s a win for the environment, your business, and consumers alike.

Ready to rethink waste and unlock smarter processing? Let’s make every core count.

Contact us today

Smart Automation is a win win for the environment, processors and consumers!

Let’s look at hand cut - versus - smart automation

In a typical hand cut processing facility, food loss during production can be high - with typical processing yields in the region of 80% - 85%

Meaning that along with the core, a large percentage of good or edible crop is also removed and discarded.

Representing a minimum of 15% of the crop that does not make it to the consumer - Food loss at source!

Smart Automation can significantly improve processor yield, by cutting food loss at source.

Each robot can de-core 55 heads of iceberg lettuce per minute, with typical yields ranging from 92% to 97%

Smart automation ensures near-zero food loss at source, preserving everything except the core for maximum processor yield and efficiency

In this typical example of robotically de-cored iceberg lettuce, the entire head remains fully intact - only the core has been cleanly and precisely removed.

Equip the Line

-

Smart De-Coring for Demanding Lines

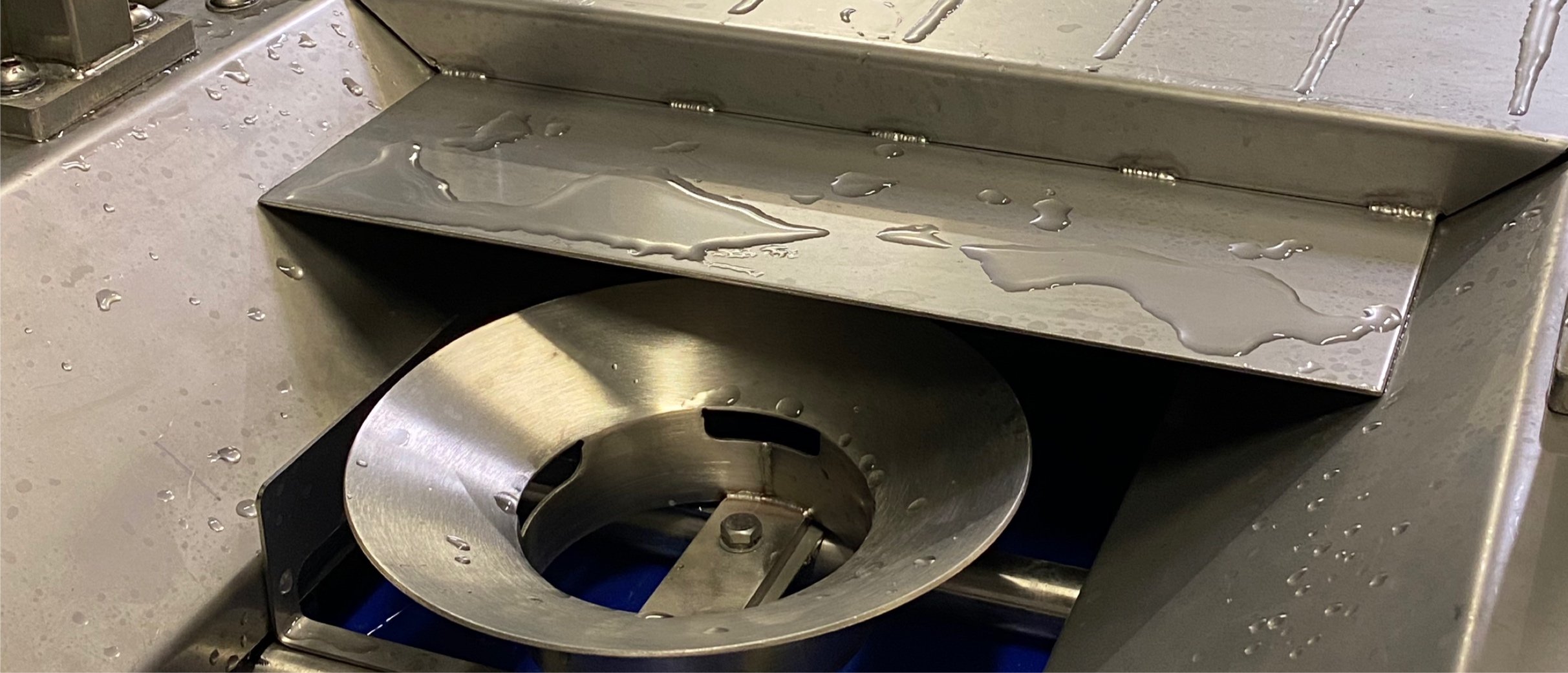

Our robotic cells are built from premium 304L/316L stainless steel, for uncompromising hygiene and durability.

Designed to the highest food-grade specifications and fully compliant with industry safety standards, they deliver simplicity, strength, and precision.

These smart machines are engineered to keep your operation clean, efficient, and ahead of the curve.

-

What's Inside

Powered by iconic FANUC yellow robots, our de-coring systems bring longevity and reliability to your processing line.

Equipped with advanced AI vision and intuitive HMI controls, our robotics integrate seamlessly into your operation.

Smart automation and real-time data analytics, optimize precision and efficiency, ensuring yields of 92%–97% while minimizing food waste.

Extractacore empowers your facility with intelligent automation - helping to facilitate sustainable processing.

-

Blazing Through Iceberg with Extractacore Robots

Our robots are built to dominate high-volume whole head iceberg processing, de-coring with relentless speed and precision.

A single pallet of crates? Done in under 15 minutes. With each bot powering through 55 heads per minute, Extractacore turns pallets into perfectly processed produce in record time.

Engineered for efficiency, our systems keep any salad processing line moving fast, maximizing yields and minimizing waste with every crate.

Achieve the Goal

-

Begin with a Pallet of Iceberg ......

Our robotic de-coring cell tackled an entire pallet of iceberg lettuce in just under 15 minutes, with only two operators.

Running at a blazing 55 heads per minute, Extractacore maximizes throughput, delivering unmatched speed and efficiency.

With yields hitting 92%–97%, our system ensures minimal waste and peak performance, making high-volume salad processing a breeze.

-

Waste Core

The Numbers Paint a Clear Picture: In a typical production run, the entire volume of waste generated from processing a full pallet is so minimal that it easily fits into a single crate, with room to spare.

Remarkably, the usable yield from that same pallet reached an exceptional 97.2%, showcasing the efficiency and precision of the process.

-

End Game

Zoom in, and you’ll see: only the core is removed, with zero excess waste.

This precision delivers exceptional product yields of 92%–97%, ensuring maximum usable lettuce flows seamlessly down your processing line.

Built for high-volume salad facilities, our technology minimizes loss and keeps your operation lean, efficient, and ready for the next step.